-

Understand Current Conditions of Equipment

-

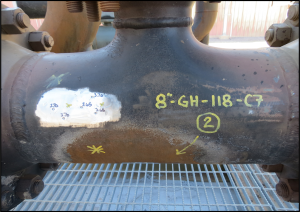

Provide Guided/Informed Instructions for NDE Inspection

-

Make Informed Repair or Replacement Decisions

Determining the metallurgical condition of a damaged component can provide information on whether it needs repair or replacement, or if it is suitable for continued service in its current condition.

A metallurgical assessment of components, combined with an understanding of the failure mechanisms of concern, can establish how much longer the component can provide reliable service. This information allows you to plan refurbishment or replacement prior to unexpected catastrophic failure or other damage.

Metallurgical condition assessment performed on components that sustain in-service degradation mechanisms can provide a benchmark as to the current condition and allow a more educated prediction of remaining useful life.

Typical mechanisms of degradation are creep, oxidation, corrosion, or metallurgical changes. Any of these conditions can progress to cause catastrophic failure. A simple test can define the condition of the component and allow a planned approach to repair or replacement to avoid forced outages.

Our metallurgical assessment services can help prevent the loss of critical components by directing maintenance efforts. We can also provide guidance to non-destructive inspection teams to direct them towards more damaged areas or pare down the work scope to avoid unnecessary inspections. Often, we partner with an NDE vendor in order to perform a more cohesive, cooperative inspection.

In order to assess the metallurgical condition of equipment components, Acuren offers a complete suite of tests.

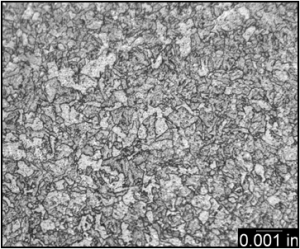

Microstructural Analysis via In-Place Metallography

Examining a component’s microstructure can reveal deterioration from corrosion, cracking, thermal aging, or mechanical deformation. Accurate assessment provides important data for determining equipment condition and remaining life. Samples are analyzed for metallurgical and manufacturing defects and internal and external surface discontinuities.

Examining a component’s microstructure can reveal deterioration from corrosion, cracking, thermal aging, or mechanical deformation. Accurate assessment provides important data for determining equipment condition and remaining life. Samples are analyzed for metallurgical and manufacturing defects and internal and external surface discontinuities.

When examining large components that cannot be easily moved, in-place metallography is used for microstructural and crack evaluation. In-place metallography, combined with replication, allows us to examine a component’s microstructure without removing a sample from the component. The same techniques can be used on small specimens when standard preparation methods are difficult or impossible.

We evaluate the microstructure using optical microscopes and compare the results to technical literature as well as our internal glossary of microstructures.

In-place metallography allows for a quick onsite component evaluation. It can reveal whether a component has suffered from overheating or other microstructural damage that nondestructive evaluation techniques cannot detect. We have three portable metallography laboratories that can be dispatched within hours of a request.

As a specific example, we have been able to produce replicas of turbine blade microstructures and determine if any gamma prime coarsening has occurred. This allows an evaluation of the blades without consuming these expensive parts for destructive evaluation of the microstructure. This can help determine if the blades are suitable for continued operation or if they need replacement.

Scale and Deposit Analysis

Scaling and deposit buildup can reduce efficiency by acting as barriers to heat transfer, promote corrosion by acting as concentration sites for corrosive species, or can result from corrosive attack. Samples are collected during on-site inspections and taken back to our laboratory for analysis. We employ energy dispersive X-ray spectroscopy and powder X-ray diffraction to identify constituents in a sample. Scale and deposit analysis can determine the nature, sources, and effects of deposits. We then suggest steps you can take to mitigate their formation.

Chemical Analysis

Equipment operates best when all of the parts are made of the correct materials. Using an XRF gun, we quantitatively analyze alloying and trace elements in the component and compare the test results with the appropriate alloy specification. We then bring any discrepancies to your attention. These results are also compared to the results of in-place metallography for consistency.

Portable Hardness Testing

Portable Hardness Testing

Hardness and dimensional measurements add to our assessment of the component’s condition. Acuren can measure the hardness of components in the field using a Microdur™ or an Equotip™ tester. Hardness data is used to estimate the tensile strength of steels or to determine if a component has experienced thermal softening. Portable hardness testing is often used in conjunction with in-place metallography/replication to provide a thorough assessment of the metallurgical condition of components in the field.

Independent Third-Party Laboratory Services

As an independent third party laboratory, Acuren – Austin has performed well over 5,000 formal multi-party investigations, accident investigations, and failure analyses since 1977. We provide litigation support to insurance and legal industries by way of documentation reviews, material evaluations, laboratory testing, technical reporting, and expert witness testimonies.

More information about these services is available on our Independent Third-Party Laboratory page.

For a Print Friendly brochure, click the link below.

Field Metallurgical Condition Assessment Services Brochure