-

Use Hanger Surveys and Visual Inspections to Monitor the “Health” of Your Piping System

-

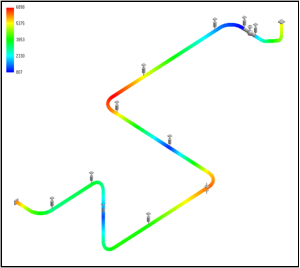

Stress Analyses to Identify Areas of High Stress

-

Recommend Locations for Non-Destructive Testing and Appropriate Testing Method(s)

-

Determine a System’s Fitness for Continued Service

With continued aging of power and steam generation units, the integrity of high-energy piping (HEP) systems becomes a growing concern. The sudden release of high pressure, superheated steam could result in catastrophic damage to plant equipment, building structure, lengthy lost production and lost revenue, or even worse, personnel injury or fatality.

Neglecting to monitor the “health” of your HEP is simply not an option. In today’s business environment, due diligence must be shown to determine a piping system’s fitness for continued service. Fortunately, this doesn’t necessarily require breaking the bank. With Acuren’s experience and knowledge of the damage mechanisms that negatively impact HEP systems, we can provide prudent engineering analysis, judgment, and testing to help you manage the reliability and integrity of your HEP through a High Energy Piping Assessment.

Piping Stress Analysis

Topped out, bottomed out, or stagnant hangers cause elevated stress. This condition leads to load shedding to adjacent piping sections making it difficult to determine exactly where elevated stresses are located and their magnitude. Piping stress analysis can help answer these questions. Once identified, inspection efforts can be concentrated on locations of high priority.

Hanger Adjustments & Load Testing

Once problematic hangers have been identified and possible damage has been accessed, it is prudent to return all pipe supports to full functionality. This may be as easy as adjusting a hanger to eliminate a topped-out or bottomed-out condition, or hanger load testing may be necessary to ensure full functionality. In either case, Acuren can assist with this effort to return the full flexibility of the HEP system.

Hanger Surveys and Piping Inspections

Hanger Surveys and Piping Inspections

Hanger surveys and piping inspections are key to monitoring the condition of a HEP system. Bottomed out, topped out, or stagnant pipe supports are the first sign of trouble as such conditions cause elevated stress – the critical factor for many damage mechanisms. Performing routine pipe inspections can help identify piping sections that have been negatively impacted by non-optimal pipe supports. Hanger surveys and piping walk-downs should be conducted on a regular basis when the system is hot and cold, ideally semi-annually. Acuren can perform surveys or help you set up survey procedures.

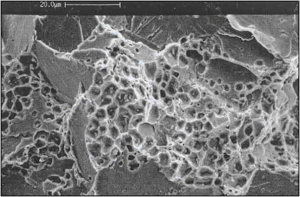

Damage Mechanisms & Inspections

Damage Mechanisms & Inspections

In the past 40 years, Acuren has conducted many HEP evaluations, as well as performed laboratory analyses on a variety of HEP components. We understand the damage mechanisms that plague HEP and can prescribe appropriate inspection methods, as well as perform the inspections. Inspection techniques often include magnetic particle inspection, dye penetrant inspection, volumetric inspection using ultrasonics, and in place metallography/replication.

For a Print Friendly brochure, click the link below.

High Energy Piping Services Brochure