-

Use Metallurgical Condition Assessment to Monitor the “Health” of Your Boiler

-

Understand the Root Cause of Failure

-

Recommend Strategies to Prevent Boiler Tube Failures

-

Predict Boiler Tubing Remaining Useful Life

Boiler tube failures are the leading cause of steam plant reliability issues. A tube failure may cause a forced outage, usually at the most inopportune time. The outage results in lost production and lost revenue.

Reducing boiler tube failures requires a two-pronged approach:

- Routine sampling for condition assessment can help monitor the “health” of a boiler, thereby preemptively mitigating damage mechanisms before they become problematic.

- Metallurgical analysis is a must for reducing the frequency of tube failures. By understanding the root cause of the failure, steps to mitigate the problem can be recommended.

The “why” of a tube failure can be determined by performing metallurgical analysis of the failed tube and intelligently combining the results with a thorough experience base to derive a failure cause.

The “why” of a tube failure can be determined by performing metallurgical analysis of the failed tube and intelligently combining the results with a thorough experience base to derive a failure cause.

Over the past forty years, Acuren has conducted well over 4,000 boiler tube analyses. Our scientists and engineers have extensive metallurgical and mechanical engineering experience, as well an understanding of boiler operation.

To address problems directly related to boiler tubes, Acuren offers six distinct services:

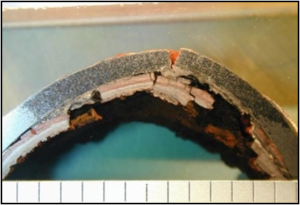

Failure Mode Determination

Failure Mode Determination

Failure mode determination can distinguish the various tube failure mechanisms such as creep, short-term overheat, corrosion, erosion, or fatigue. Once the damage mechanism has been identified, recommendations can be made to mitigate similarly affected tubes within the boiler via subsequent non-destructive testing or additional tube sampling.

Examining the boiler tube microstructure can reveal deterioration resulting from corrosion, overheating, or thermal aging. Accurate tubing assessment provides important data for determining the overall condition of your boiler.

Metallurgical Condition Assessment

Examining the boiler tube microstrucure can reveal deterioration resulting from corrosion, overheating, or thermal aging. Accurate tubing assessment provides important data for determining the overall condition of your boiler.

Remaining Life Estimation

Using industry codes and analytical techniques, we can perform remaining useful life assessments to predict future tubing reliability. For high temperature tubing, creep rupture is typically the primary life limiting damage mechanism. Using creep rupture data, remaining creep life of tubing can be estimated. For lower temperature water tubing, thinning is the common life limiting factor. Remaining life assessments can be evaluated for thinning whether it is general or localized.

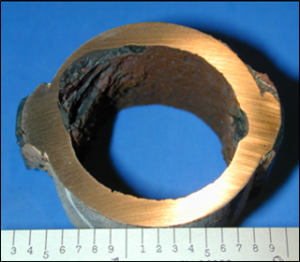

Scale and Deposit Analysis

External scaling and internal deposit buildup on boiler tubes reduce efficiency by acting as barriers to heat transfer. Analysis can determine the composition of the scale/deposit thereby providing insight about its source. Once the source has been identified, steps can be recommended for removal and mitigating future scale/deposit formation.

Internal Deposit Loading Measurement

Internal deposit loading measurement yields boiler tube cleanliness information. With this information, we can determine when a boiler requires chemical cleaning and identify special cleaning needs.

Tube Material Characterization

Equipment operates best when all the components are fabricated using the correct material with the correct properties. Acuren quantitatively analyzes alloying elements in tubes and weld metals and compares the results with the appropriate specification requirements. We also determine the strength of the material to determine if there has been degradation of the material properties. We bring any discrepancies or deficiencies to your attention.

For a Print Friendly brochure, click the link below.

Boiler Tube Assessment Services Brochure