-

Case Evaluation and Technical Data Review

-

Test Methods Development and Planning

-

Evidence Identification and Documentation

-

Laboratory Testing and Documentation

-

Critical Review of Test Data

-

Concise “easy-to-understand” Reporting

-

Depositions and Scientific Expert Testimony

-

Secure Evidence Storage and Handling

As an independent third-party laboratory, Acuren – Austin has performed well over 5,000 formal multi-party investigations, accident investigations, and failure analyses since 1977. We have provided litigation support to insurance companies, manufacturers, industrial clients, plaintiffs, and defendants by way of documentation reviews, material evaluations, laboratory testing, technical reporting, and expert witness testimonies.

As an independent third-party laboratory, Acuren – Austin has performed well over 5,000 formal multi-party investigations, accident investigations, and failure analyses since 1977. We have provided litigation support to insurance companies, manufacturers, industrial clients, plaintiffs, and defendants by way of documentation reviews, material evaluations, laboratory testing, technical reporting, and expert witness testimonies.

Our highly trained engineers, scientists, and laboratory technicians encompass a myriad of expertise in conducting comprehensive accident investigations and failure analyses. Most of our multidisciplinary staff of materials engineers, metallurgical engineers, mechanical engineers, and chemists hold advanced degrees and professional certifications. We are supplemented further by a network of professionals in chemical,

environmental, and process engineering, as well as equipment design.

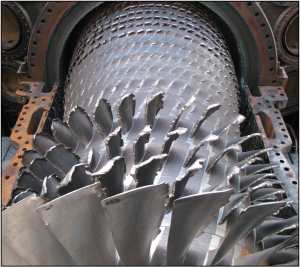

The diversity of our staff and our extensive technical experience enable us to establish the root cause of accidents or failures. Whether in the field or in the laboratory, we draw on our in-depth knowledge of the equipment and processes used in the utility, pulp and paper, petrochemical, pharmaceutical, manufacturing, and other industries, to provide our clients with the most reliable and concise test results, technical reporting, and expert testimony.

The diversity of our staff and our extensive technical experience enable us to establish the root cause of accidents or failures. Whether in the field or in the laboratory, we draw on our in-depth knowledge of the equipment and processes used in the utility, pulp and paper, petrochemical, pharmaceutical, manufacturing, and other industries, to provide our clients with the most reliable and concise test results, technical reporting, and expert testimony.

Independent Third-Party Laboratory Services

Acuren – Austin offers independent, third-party inspections in our 1900 square foot litigation support facility, consisting of a laboratory area, two meeting rooms, and a private office space.

Acuren – Austin offers independent, third-party inspections in our 1900 square foot litigation support facility, consisting of a laboratory area, two meeting rooms, and a private office space.

The laboratory area covers 1390 square feet and houses a photography station, disassembly area, stereomicroscope with digital camera, and a metallurgical microscope. All cameras in the laboratory area are linked to a 55” television monitor located within the laboratory area for group viewing.

Each meeting room is equipped with a 48” television monitor which is also linked to our stereomicroscope, and metallurgical microscope; allowing participants to witness examinations in all meeting spaces.

Below are some of the typical laboratory support services available. Each case is tailored to the needs of the parties involved.

- Inventory and Photographic Documentation of Parts/Materials

- Documentation of Serial Numbers, Model Numbers, Lot Numbers, Part Numbers, etc.

- Low Magnification Examination and Photographic Documentation Using a Stereomicroscope

- Sectioning and Preparation of Specimens for Fractographic and Metallographic Examination

- Metallographic Examination of Specimens and Photographic Documentation Using a Metallurgical Microscope

- Hardness and/or Microhardness Testing of Specimens

- Scanning Electron Microscopy (SEM) Examination/ Energy Dispersive Spectroscopy (EDS) Analysis

- Identification of Material Composition Using Optical Emissions Spectroscopy (OES)

Our litigation support facility is adjacent to Acuren – Austin’s Materials Science Laboratory and machine shop, which can perform additional testing including non-destructive examination (NDE) such as wet and dry magnetic particle inspection and dye penetrant inspection, pressure testing, electrical testing, functionality testing, etc.

For a Print Friendly brochure, click the link below.

Litigation Support Services