Access the Boiler Tube Failure Handbook.

How to Use the Handbook

The visual appearance of a failed boiler or HRSG tube provides valuable information regarding the mechanism of failure. Determining the failure mechanism is the first step of the failure reduction/elimination process. The process includes the following steps:

- Determine Failure Mechanism

- Find Root Cause of the Failures

- Determine the extent of the damage

- Find and implement short-term solutions

- Find and implement long-term solutions to prevent re-occurrence

The handbook presents examples of common failure mechanisms in a variety of boilers including power boilers, recovery boilers, and Heat Recovery Steam Generators (HRSGs). Visual examination may help the equipment operator decide whether further metallurgical examination and root cause analysis is warranted. The only sure way to determine a failure mechanisms and root cause is a full metallurgical examination.

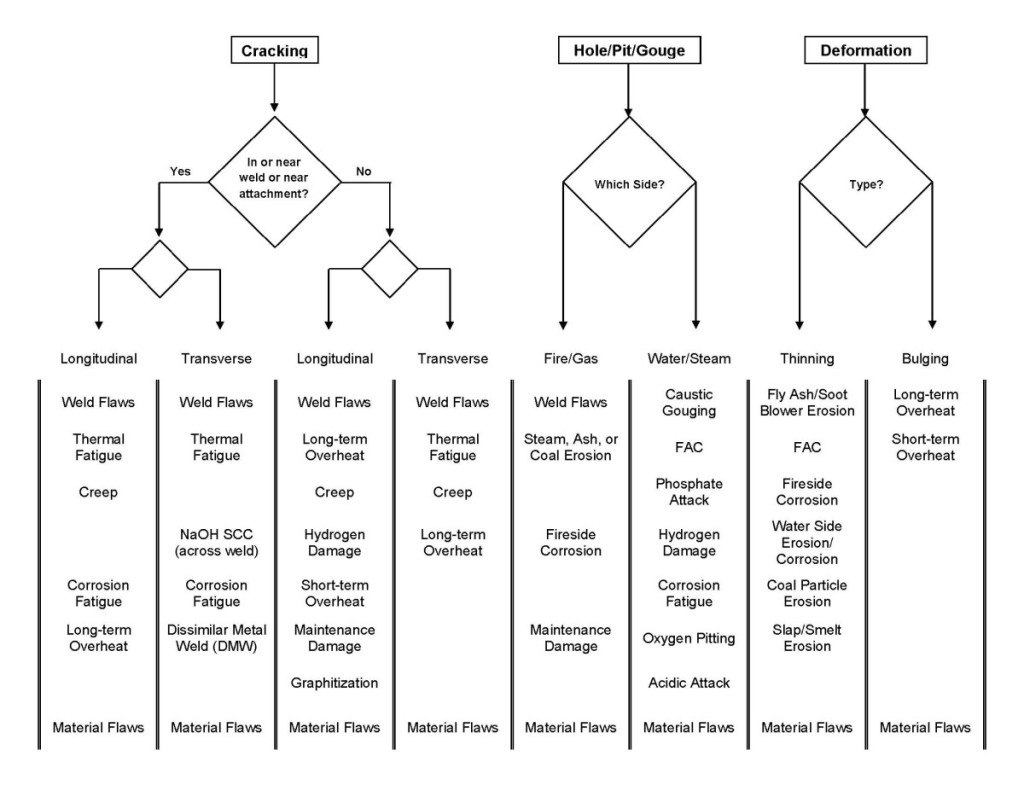

The flow chart presented below will help you determine which mechanisms are possible given the appearance of the failure. Some mechanisms can manifest themselves by a variety of appearances. The Handbook divides these mechanisms into three classifications: cracks, holes/pits/gouges, and deformation.

Cracks near a weld or attachment are a separate category from those away from these stress concentrators. Holes, pits and gouges are three examples of corrosion and may occur on the fire/gas side or on the water/steam side of the tube. Deformation includes thinning from the water or fireside and bulging or blistering.

Cracks near a weld or attachment are a separate category from those away from these stress concentrators. Holes, pits and gouges are three examples of corrosion and may occur on the fire/gas side or on the water/steam side of the tube. Deformation includes thinning from the water or fireside and bulging or blistering.

Often more than one of these characteristics can appear in a failure. Bulging can create cracks in the metal surface, and thinning can result in holes and cracks in the surface. For this reason, mechanisms may appear in more than one category. When making a preliminary identification of a mechanism, it is often helpful to look at other examples of the same mechanism listed under a different section. These are cross-referenced on each example for convenience. We repeat: the only sure way to determine a failure mechanism and root cause of failure is to perform a full metallurgical examination.