-

Metallurgical Examination

-

Fractography

-

SEM Elemental Analysis

-

Hardness Testing

-

Customized Component Testing

-

Compositional Analysis

Acuren’s has multiple Materials Science Laboratories, with Acuren – Austin located just outside of Austin in Leander, TX. We offer a variety of services ranging from metallographic examination to materials evaluation on a scanning electron microscope (SEM). All tests are performed according to ASTM or other standardized specifications.

The fully equipped laboratory also accommodates client-designed projects requiring nonstandard test rigs or conditions. Supporting Acuren’s activities worldwide, the Materials Science Laboratory is staffed by an experienced team of technicians.

The laboratory supports our engineers and scientists in the materials, mechanical, and metallurgical disciplines to service a diverse set of clients. We have large, color monitors and seating in the SEM, metallograph, and stereomicroscope rooms for our clients to witness testing if so desired.

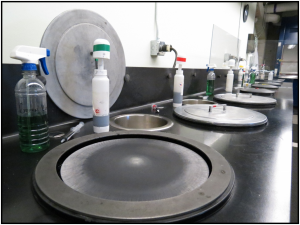

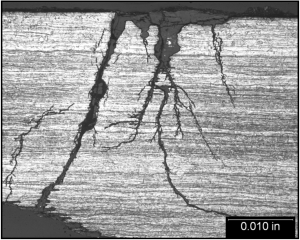

Metallurgical Sample Preparation and Examination

Acuren’s technicians can metallographically prepare and document the microstructure of a wide range of materials. Our laboratory has metallographic equipment for sectioning, grinding, polishing, and etching metals, ceramics, plastics, and composites. Metallographs are equipped with digital cameras with calibrated magnification. We also have two portable metallographic laboratories that allow our engineers and technicians to perform metallography in the field on large components or where examination by only nondestructive techniques is desired.

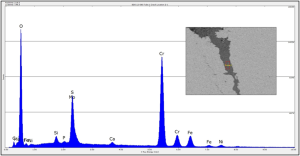

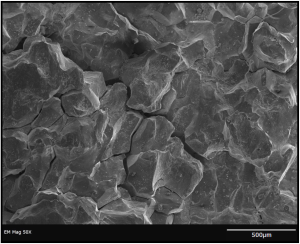

SEM Analysis

Acuren has a scanning electron microscope (SEM) equipped with an energy-dispersive X-ray analyzer. The SEM has image processing capabilities for mapping elemental constituents, as well as particle sizing and counting. These capabilities are useful for examining preferential corrosion, deposit layering, coating layers, etc. This equipment is suited for high-magnification viewing and photography, and semi-quantitative compositional analyses on metals, ceramics, and powder samples. Elements as light as carbon can be detected. The equipment includes a silicon drift detector that makes gathering and processing composition data much more efficient to allow more samples to be analyzed in a day. We can accept samples up to 7 inches long by 7 inches wide by 3 inches high. Sputter coating is also available for examination of non-conductive parts or deposit samples.

The SEM is particularly useful for fractography to examine fracture surfaces and determine failure mode(s). We routinely examine samples at up to 10,000 times magnification, but can go as high as 70,000X depending on the features being examined. This high level of magnification is useful for observing evidence of fatigue, gamma prime aging, brittle fracture, and other metallographic features.

Hardness Testing

Acuren can perform both macro (Rockwell and Brinnel) and microhardness measurements using calibrated test equipment. We can also perform hardness tests in the field using portable hardness testers.

Component Testing

Many of our services can be used to perform component reliability or performance testing. Special test rigs can be constructed to cycle components mechanically to determine their endurance, compare the performance of equipment from different component manufacturers, or compare results to required performance criteria. Leak testing can also be performed on tubes, pipes, or other small vessels. We have also performed testing on thermostats, switches, and other electrical components.

Acuren’s laboratories can accommodate metals, ceramics, rubber, composites, and plastics used in valves, bearings, piping, welded shafts, and many other components.

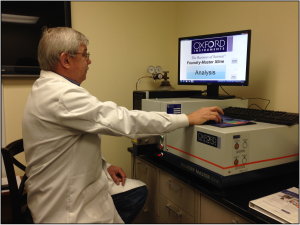

Compositional Testing

Acuren’s Oxford Instruments Foundry-Master Xline spectrometer (OES) allows for certified compositional analysis of carbon, low alloy and stainless steel materials. This allows for material identification within 24 hours, complementing our other metallurgical and analytical services including metallographic sample preparation, hardness and microhardness testing, energy dispersive X-ray spectroscopy (EDS) and scanning electron microscopy (SEM).

Other Testing Available

Acuren has three laboratories within the U.S. performing routine testing. Examples of services that are available to compliment the Acuren – Austin laboratory include chemical testing (ICP, etc.), tensile testing, charpy impact testing, X-ray diffraction (XRD), FT-IR analysis, and polymer property and identification testing (e.g., Shore hardness and GCMS).

Independent Third-Party Laboratory Services

As an independent third-party laboratory, Acuren – Austin has performed well over 5,000 formal multi-party investigations, accident investigations, and failure analyses since 1977. We provide litigation support to insurance and legal industries by way of documentation reviews, material evaluations, laboratory testing, technical reporting, and expert witness testimonies.

More information about these services is available on our Independent Third-Party Laboratory Services page.

For a Print Friendly brochure, click the link below.

Materials Laboratory Services Brochure

Materials Laboratory Services Brochure (Spanish)